Check out the new Battery Cycler Simulator

Check out the new Battery Cycler Simulator

Accelerate Your Battery Innovation

Accelerate Your Battery Innovation

Accelerate Your Battery Innovation

Run simulations before building prototypes, reduce costly lab tests, and bring products to market faster with Ionworks.

Run simulations before building prototypes, reduce costly lab tests, and bring products to market faster with Ionworks.

Run simulations before building prototypes, reduce costly lab tests, and bring products to market faster with Ionworks.

All-in-one battery simulation platform

All-in-one battery simulation platform

All-in-one battery simulation platform

All-in-one battery simulation platform

Battery simulations are notoriously challenging to get right. A small tweak in parameters, model assumptions, or operating conditions can drastically shift your predicted outcomes. Our all-in-one platform supports you from initial design through to final validation.

Test Multiple Scenarios Instantly

Quickly explore different conditions and chemistries without building prototypes. Adjust parameters and immediately see how performance metrics change, so you can identify promising designs early on.

Test Multiple Scenarios Instantly

Quickly explore different conditions and chemistries without building prototypes. Adjust parameters and immediately see how performance metrics change, so you can identify promising designs early on.

Test Multiple Scenarios Instantly

Quickly explore different conditions and chemistries without building prototypes. Adjust parameters and immediately see how performance metrics change, so you can identify promising designs early on.

Test Multiple Scenarios Instantly

Quickly explore different conditions and chemistries without building prototypes. Adjust parameters and immediately see how performance metrics change, so you can identify promising designs early on.

Use State-of-the-Art Models

Rely less on guesswork and more on evidence when refining your battery designs and tests. Use detailed electrochemical and data-driven models that closely approximate how cells behave in real use.

Use State-of-the-Art Models

Rely less on guesswork and more on evidence when refining your battery designs and tests. Use detailed electrochemical and data-driven models that closely approximate how cells behave in real use.

Use State-of-the-Art Models

Rely less on guesswork and more on evidence when refining your battery designs and tests. Use detailed electrochemical and data-driven models that closely approximate how cells behave in real use.

Use State-of-the-Art Models

Rely less on guesswork and more on evidence when refining your battery designs and tests. Use detailed electrochemical and data-driven models that closely approximate how cells behave in real use.

Adjust Parameters with Ease

Change design parameters like electrode thickness, active material loading, or particle size. Experiment more efficiently without writing code or building physical prototypes.

Adjust Parameters with Ease

Change design parameters like electrode thickness, active material loading, or particle size. Experiment more efficiently without writing code or building physical prototypes.

Adjust Parameters with Ease

Change design parameters like electrode thickness, active material loading, or particle size. Experiment more efficiently without writing code or building physical prototypes.

Adjust Parameters with Ease

Change design parameters like electrode thickness, active material loading, or particle size. Experiment more efficiently without writing code or building physical prototypes.

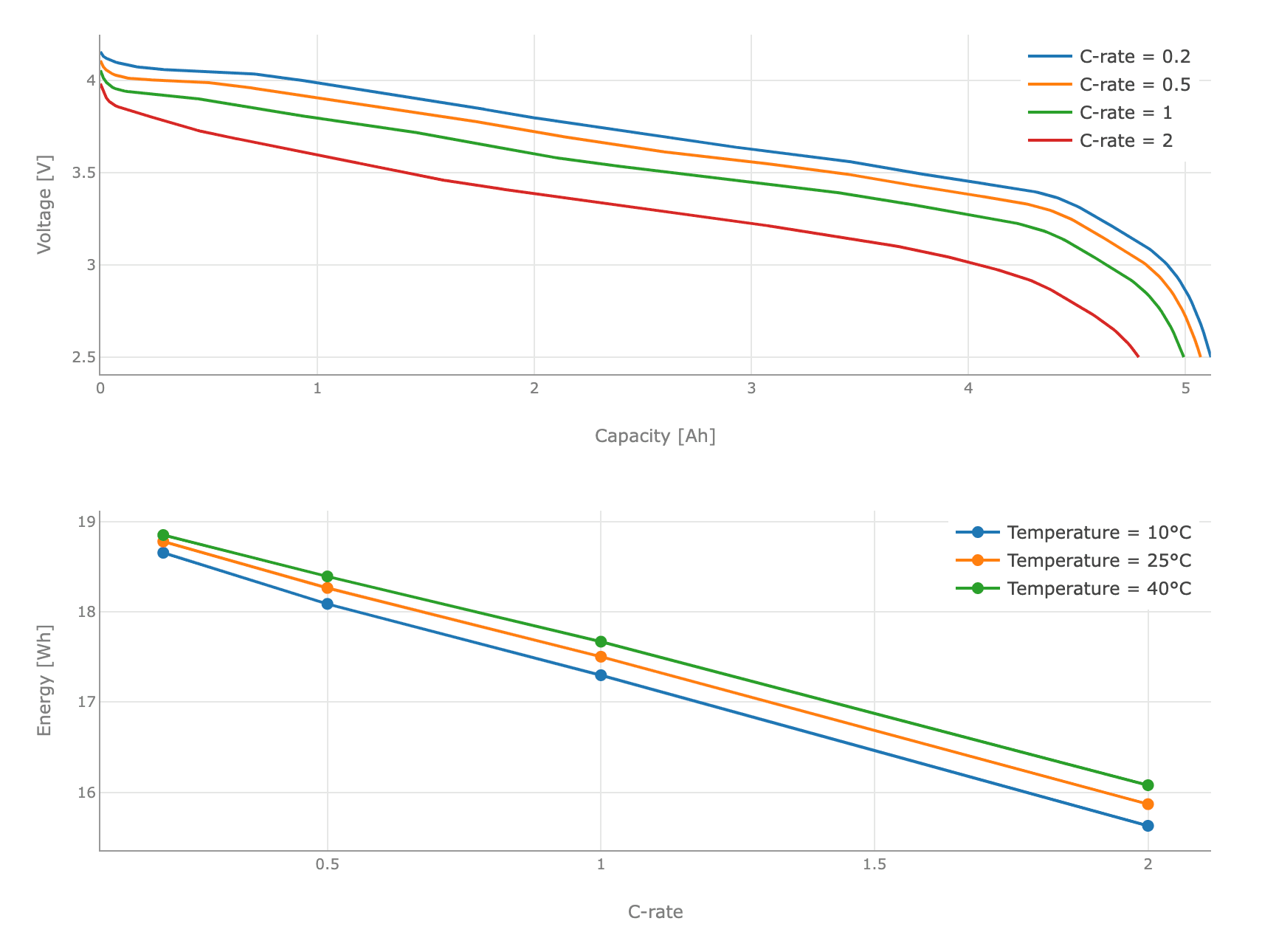

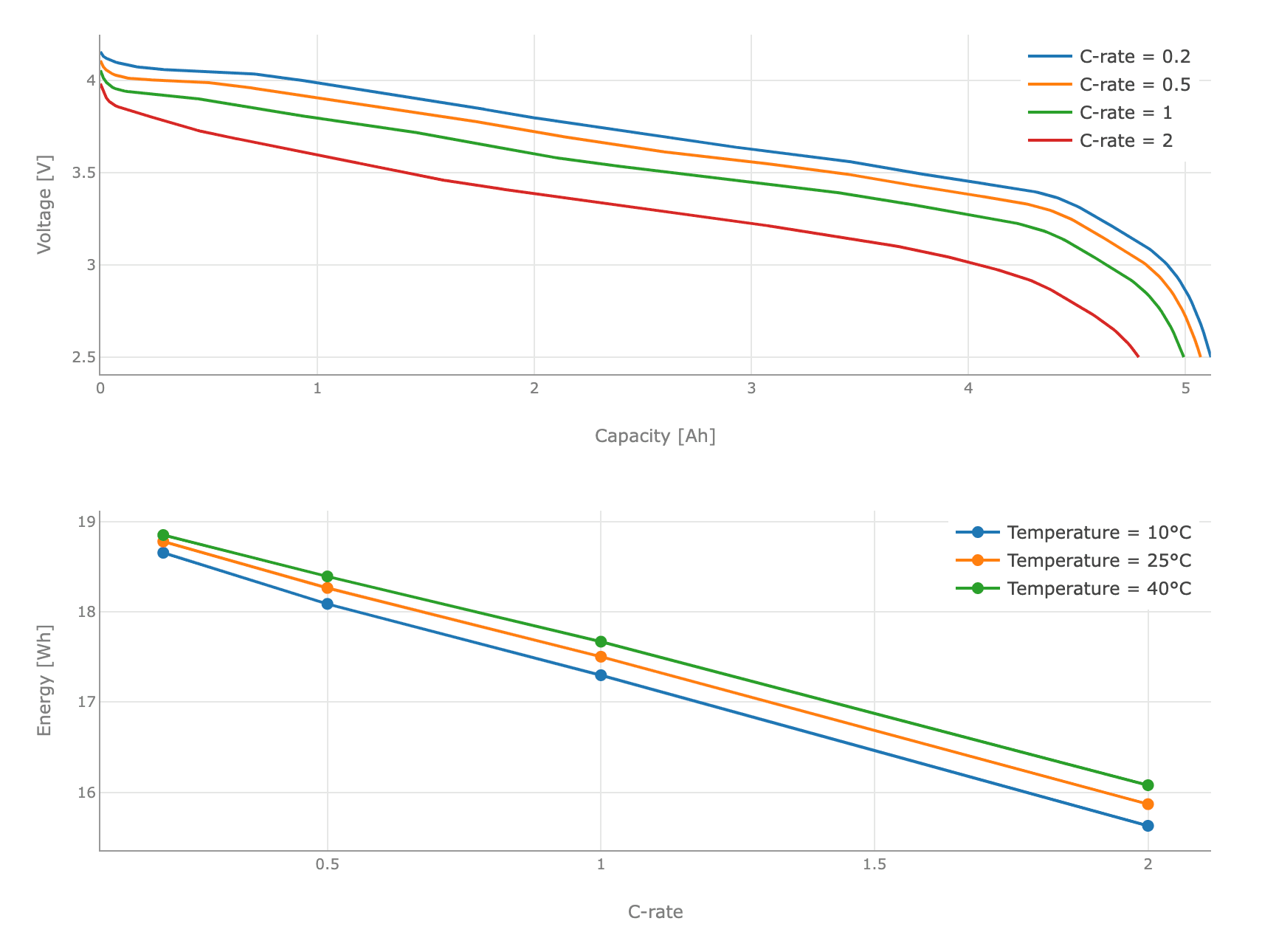

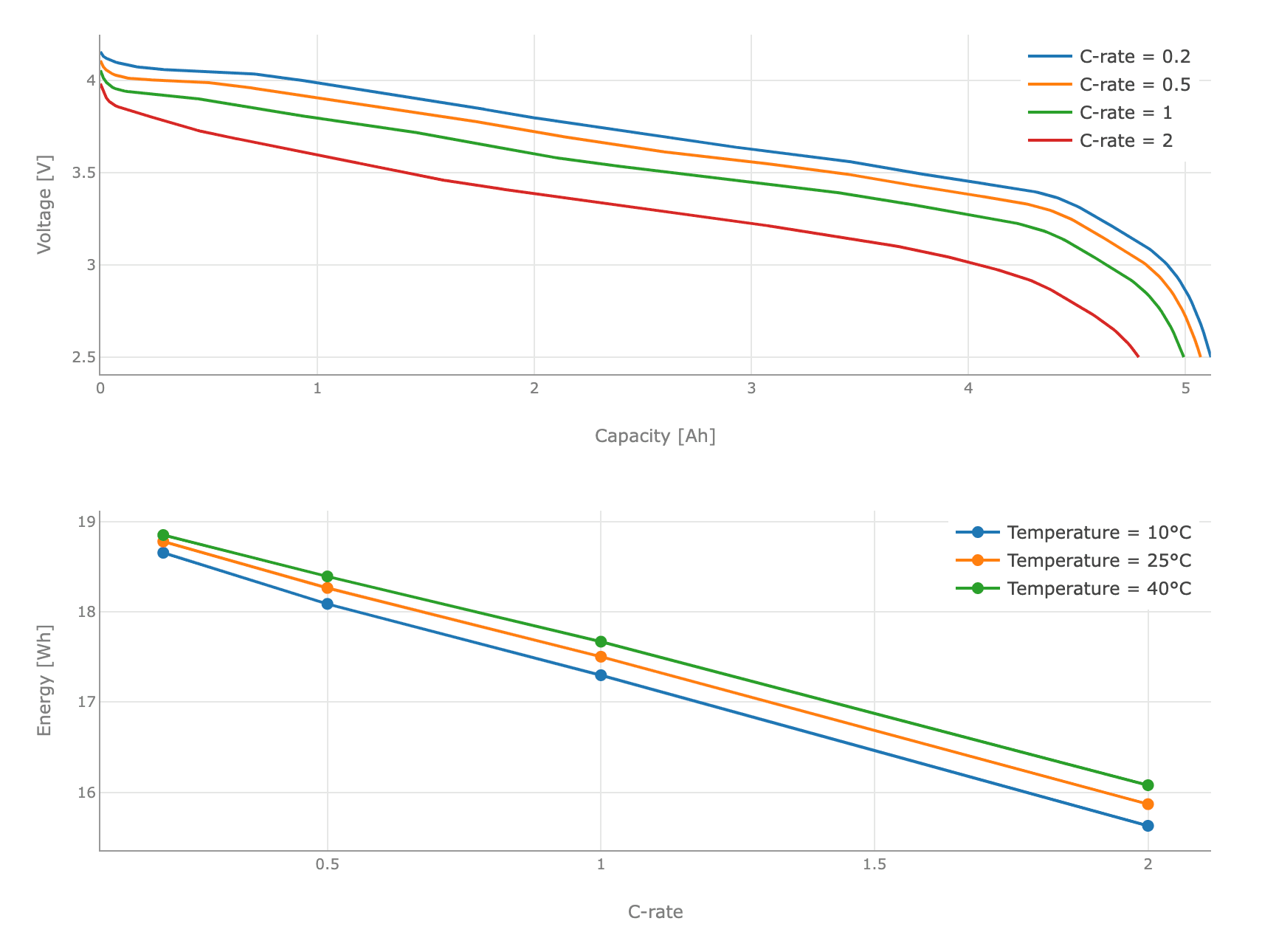

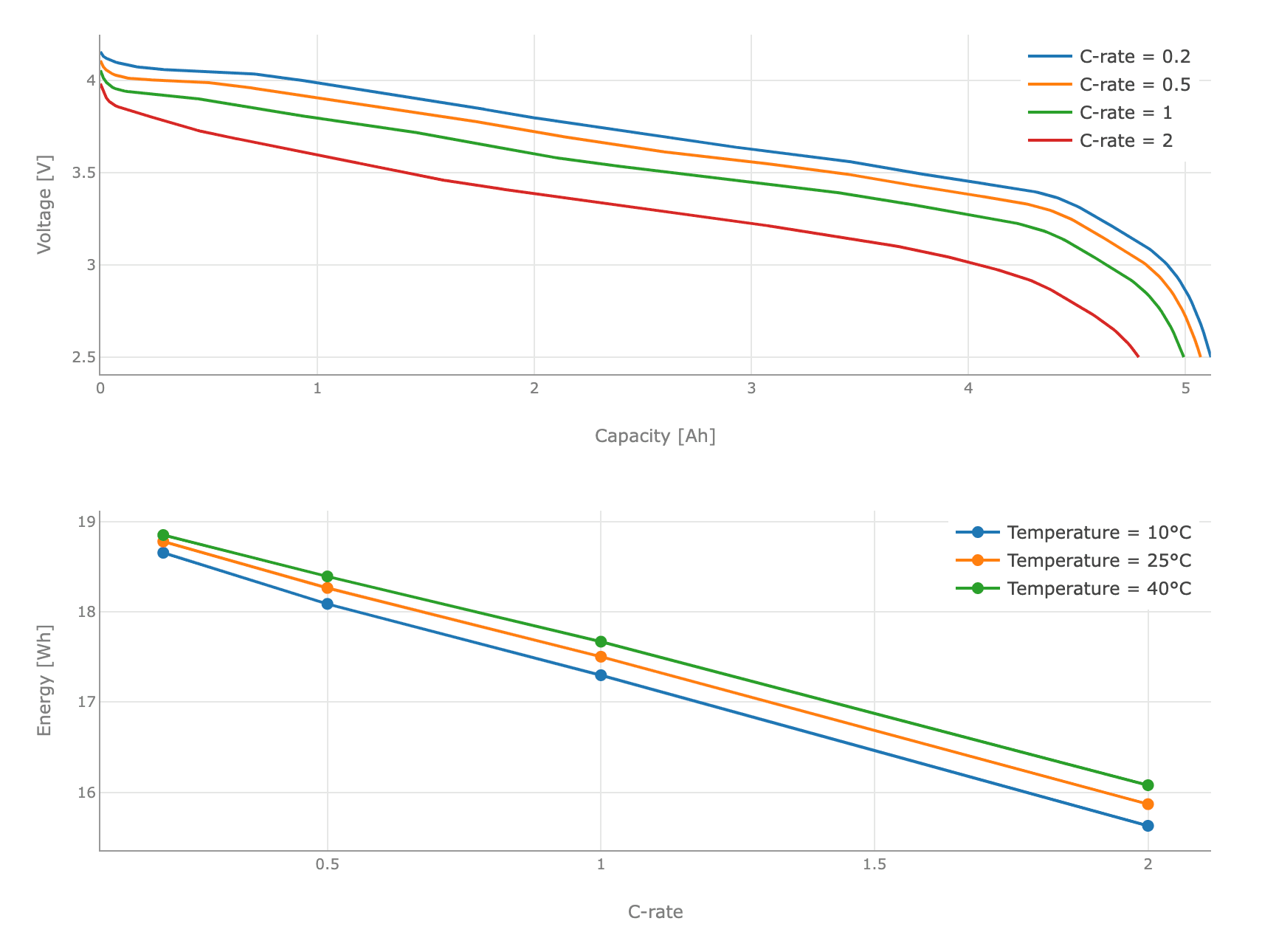

Visualize Results at a Glance

Convert raw simulation data into straightforward charts and graphs. By seeing how metrics like capacity or energy density evolve, you can spot trends and issues without sifting through complex data sets.

Visualize Results at a Glance

Convert raw simulation data into straightforward charts and graphs. By seeing how metrics like capacity or energy density evolve, you can spot trends and issues without sifting through complex data sets.

Visualize Results at a Glance

Convert raw simulation data into straightforward charts and graphs. By seeing how metrics like capacity or energy density evolve, you can spot trends and issues without sifting through complex data sets.

Visualize Results at a Glance

Convert raw simulation data into straightforward charts and graphs. By seeing how metrics like capacity or energy density evolve, you can spot trends and issues without sifting through complex data sets.

Compare and Track Improvements Over Time

Keep a record of past simulations and compare them side-by-side. Understand how small adjustments impact long-term performance, helping you refine your approach more systematically.

Compare and Track Improvements Over Time

Keep a record of past simulations and compare them side-by-side. Understand how small adjustments impact long-term performance, helping you refine your approach more systematically.

Compare and Track Improvements Over Time

Keep a record of past simulations and compare them side-by-side. Understand how small adjustments impact long-term performance, helping you refine your approach more systematically.

Compare and Track Improvements Over Time

Keep a record of past simulations and compare them side-by-side. Understand how small adjustments impact long-term performance, helping you refine your approach more systematically.

Collaborate Seamlessly with Your Whole Team

Share simulations, comment on outcomes, and discuss next steps within a single platform. Everyone stays up-to-date and can contribute to better design decisions.

Collaborate Seamlessly with Your Whole Team

Share simulations, comment on outcomes, and discuss next steps within a single platform. Everyone stays up-to-date and can contribute to better design decisions.

Collaborate Seamlessly with Your Whole Team

Share simulations, comment on outcomes, and discuss next steps within a single platform. Everyone stays up-to-date and can contribute to better design decisions.

Collaborate Seamlessly with Your Whole Team

Share simulations, comment on outcomes, and discuss next steps within a single platform. Everyone stays up-to-date and can contribute to better design decisions.

Get Started in Three Easy Steps

Get Started in Three Easy Steps

Get Started in Three Easy Steps

Get Started in Three Easy Steps

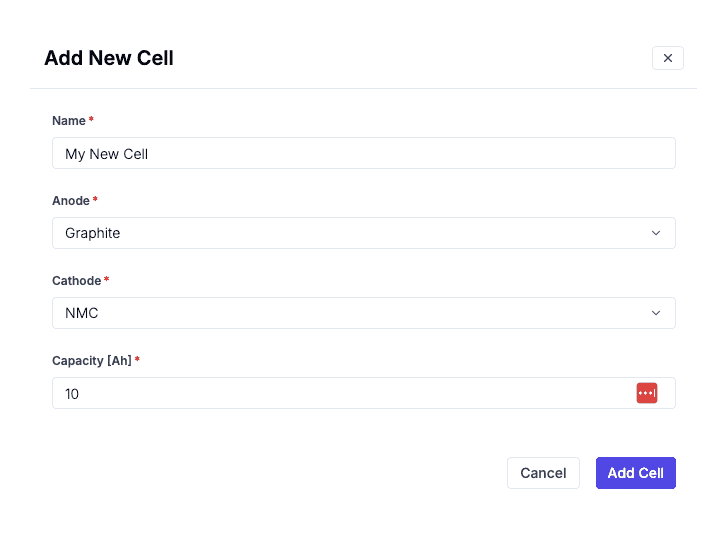

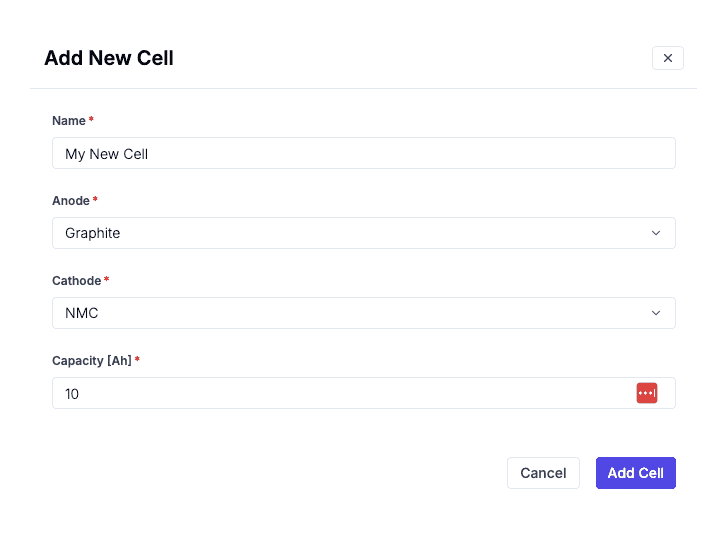

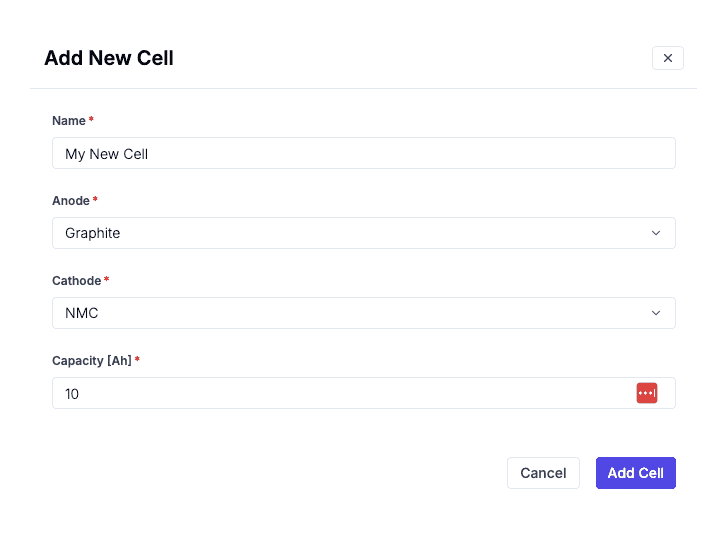

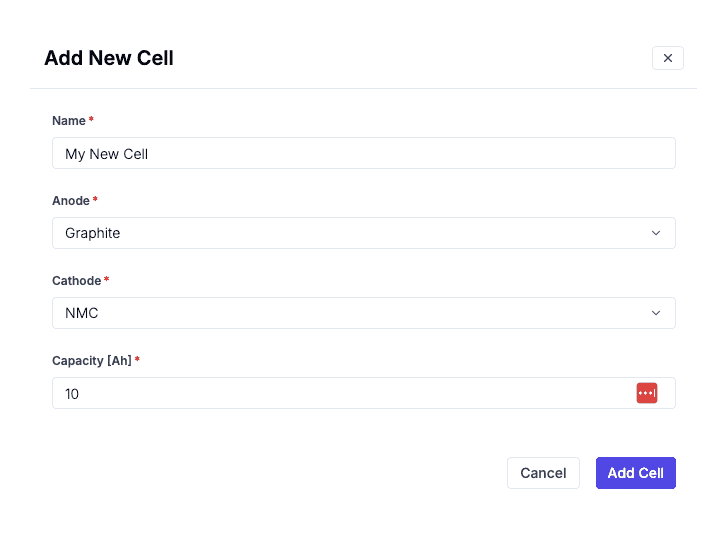

1. Create a cell

Provide the chemistry and capacity, and we’ll create a ready-to-use model for you. You can easily fine-tune it later to meet your specific needs.

1. Create a cell

Provide the chemistry and capacity, and we’ll create a ready-to-use model for you. You can easily fine-tune it later to meet your specific needs.

1. Create a cell

Provide the chemistry and capacity, and we’ll create a ready-to-use model for you. You can easily fine-tune it later to meet your specific needs.

1. Create a cell

Provide the chemistry and capacity, and we’ll create a ready-to-use model for you. You can easily fine-tune it later to meet your specific needs.

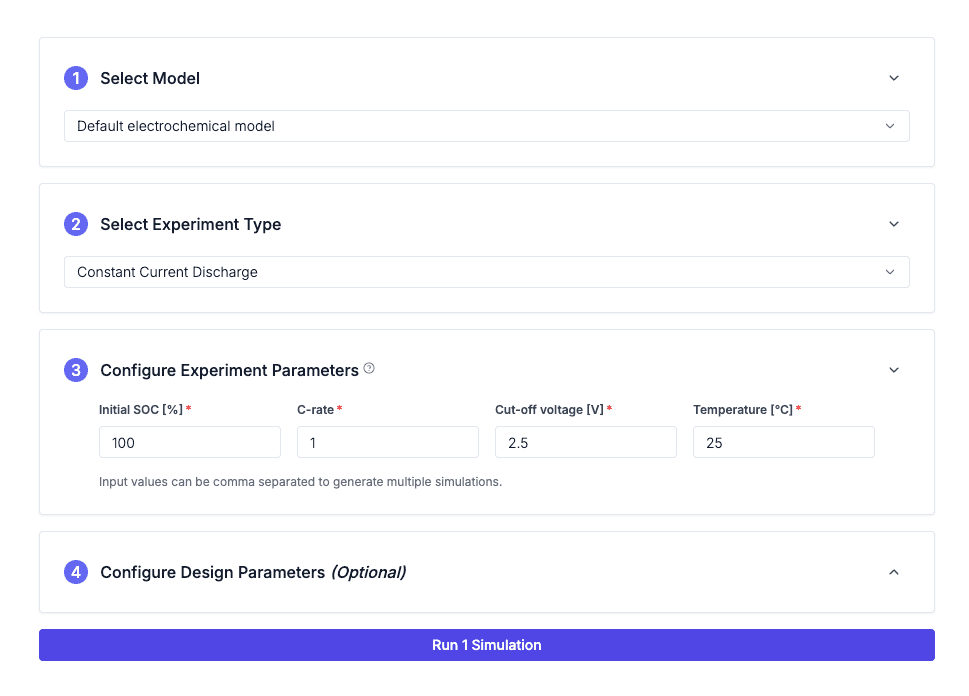

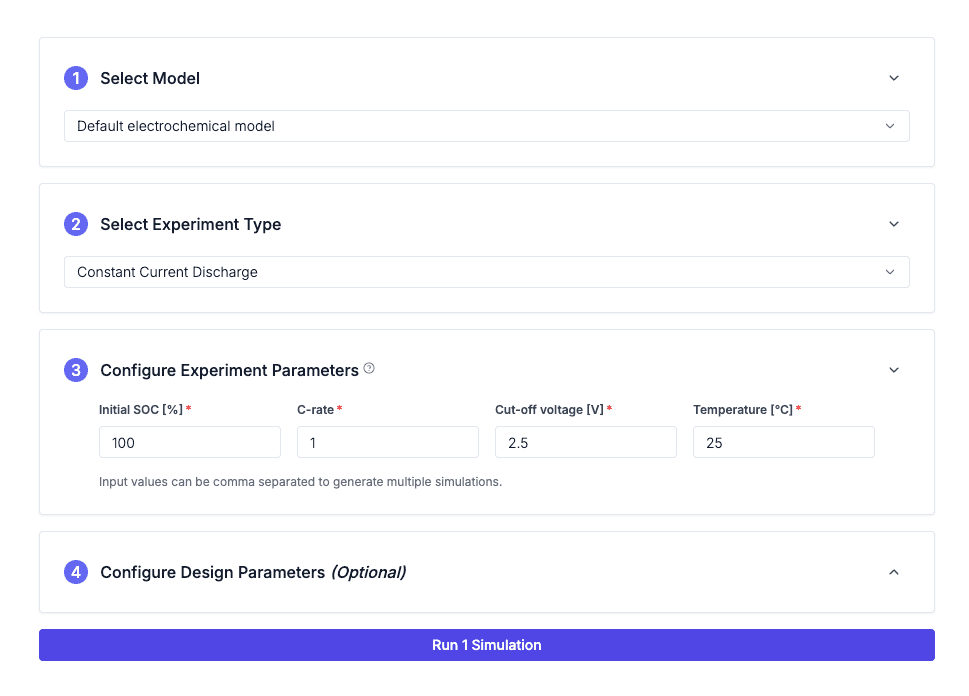

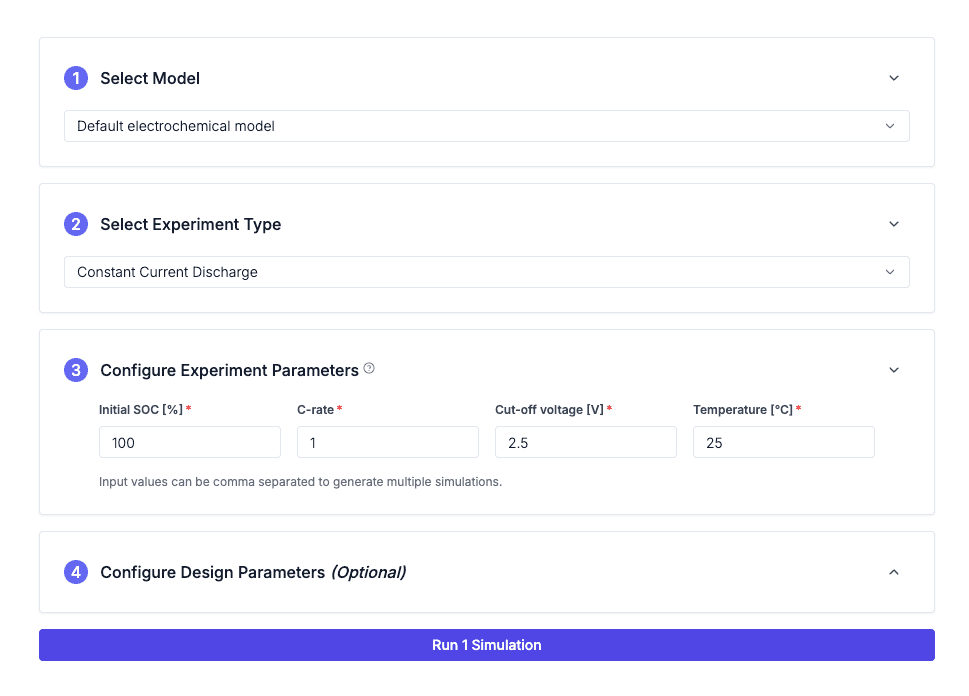

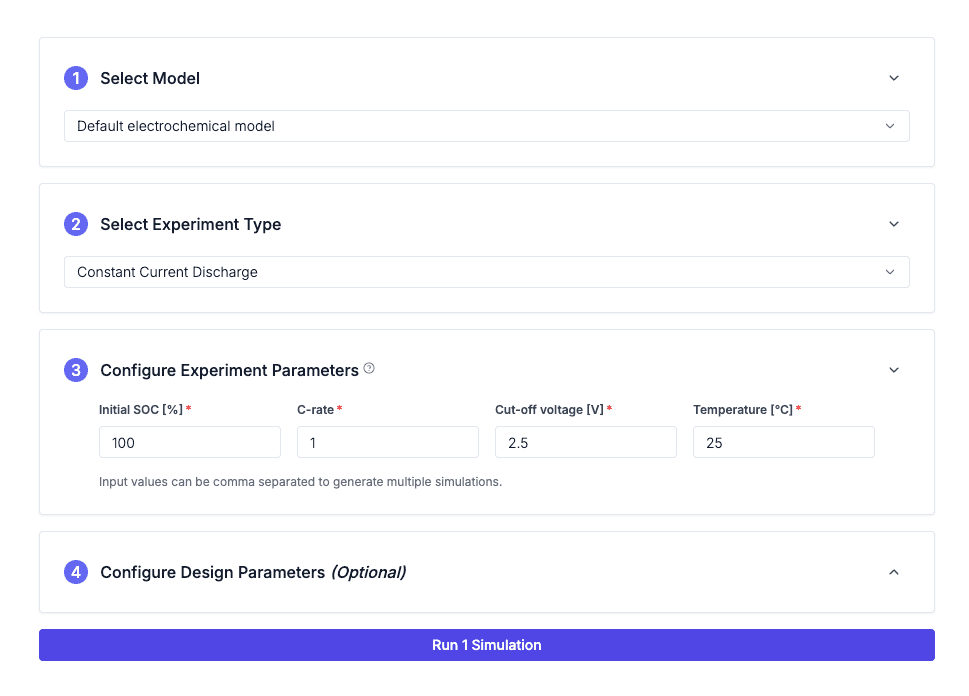

2. Run a simulation

Choose the experiment type and configure the parameters from our extensive library of predefined options, designed to cover a wide range of testing scenarios and conditions.

2. Run a simulation

Choose the experiment type and configure the parameters from our extensive library of predefined options, designed to cover a wide range of testing scenarios and conditions.

2. Run a simulation

Choose the experiment type and configure the parameters from our extensive library of predefined options, designed to cover a wide range of testing scenarios and conditions.

2. Run a simulation

Choose the experiment type and configure the parameters from our extensive library of predefined options, designed to cover a wide range of testing scenarios and conditions.

3. Visualize results

View time series results or single metrics, and compare across different operating conditions

3. Visualize results

View time series results or single metrics, and compare across different operating conditions

3. Visualize results

View time series results or single metrics, and compare across different operating conditions

3. Visualize results

View time series results or single metrics, and compare across different operating conditions

Battery Cycler Simulator

Avoid costly testing mistakes by verifying your cycler protocols before running your experiments

Run your first virtual battery test today

Simulate, iterate, and validate your cell configurations with no lab time required.

Ionworks Technologies Inc. All rights reserved.

Run your first virtual battery test today

Simulate, iterate, and validate your cell configurations with no lab time required.

Ionworks Technologies Inc. All rights reserved.

Run your first virtual battery test today

Simulate, iterate, and validate your cell configurations with no lab time required.

Ionworks Technologies Inc. All rights reserved.